This website uses cookies so that we can provide you with the best possible user experience. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helps our team understand which sections of the website are most interesting and useful to you.

Products

Here you will find a selection of products that have been developed and realized by us and are successfully used by our customers.

Be inspired by our innovative products.

Hier finden Sie eine Auswahl an Produkten, die von uns entwickelt und realisiert wurden und erfolgreich bei unseren Kunden eingesetzt werden.

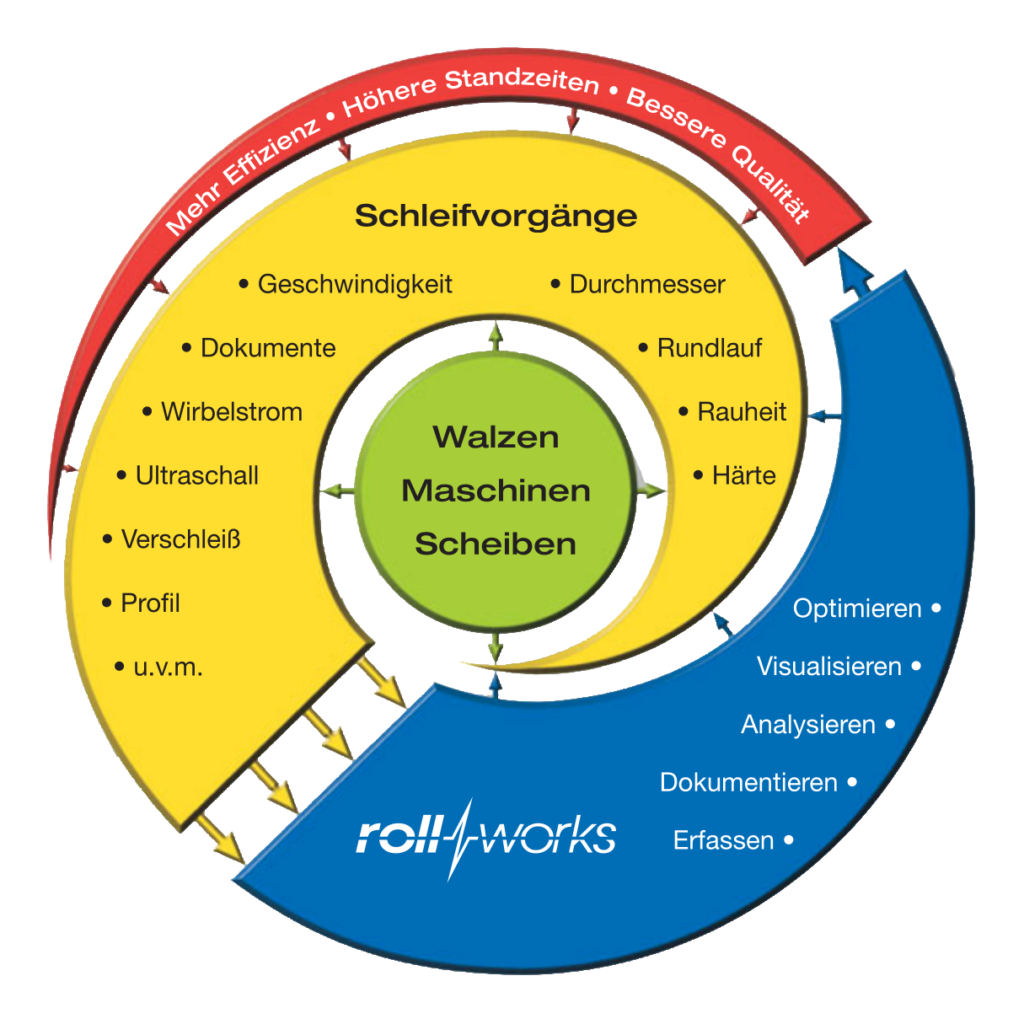

Roll Works

Roll Works is a comprehensive system for all roll processing tasks in the steel, aluminum and paper industries. It manages all essential components, such as rolls and grinding wheels, optimizes the roll grinding processes and offers comprehensive statistical evaluations of roll, wheel and grinding machine performance.

- Roll Works Overview describes the comprehensive features of Roll Works.

- Roll Works Explorer is the central application for working with Roll Works. It manages all components (rolls, grinding wheels, etc.), visualizes grinding processes, provides statistical evaluations, and much more.

- Roll Works Optimizer automatically and continuously calculates the optimal parameters during the grinding process.

- Roll Works Automation is responsible for ensuring the specifications for roll processing.

- Roll Works Management is an integrated solution for the efficient management and documentation of all operational processes.

- Roll Works Communication Center is the central interface between all Roll Works components.

- Roll Works Vibration Monitor minimizes the possible surface defects, such as chatter marks.

LVS

LVS is a comprehensive warehouse management system for the metal industry, which – focused on process automation and optimization – implements logistics tasks related to storage as well as supply and disposal of connected production facilities (rolling mills, galvanizing plants, slitting lines, etc.).

- LVS Server is the central component that implements all external interfaces, the control of the integrated modules (LVS Crane, LVS Shuttle, etc.), and the actual data management.

- LVS Crane integrates the signal acquisition and analysis to the sensor technology required on cranes and implements the visualization tasks necessary for the crane operator and ground personnel.

- LVS Shuttle was developed for the fully automatic control of a shuttle for the transport of goods, such as coils.

Task Manager

Our Task Manager is a powerful tool that helps companies manage their workflows efficiently. It offers functions for intelligent task planning, progress tracking and collaboration. The integration of AI enables optimized resource planning and more efficient work processes.

- Efficient resource planning: Track progress and optimize the use of your resources.

- Customizable views: Customize how your tasks are displayed.

- Seamless collaboration: Link files and attachments directly to tasks for better teamwork.

Devices